BIOGAS PLANTS COMPACT

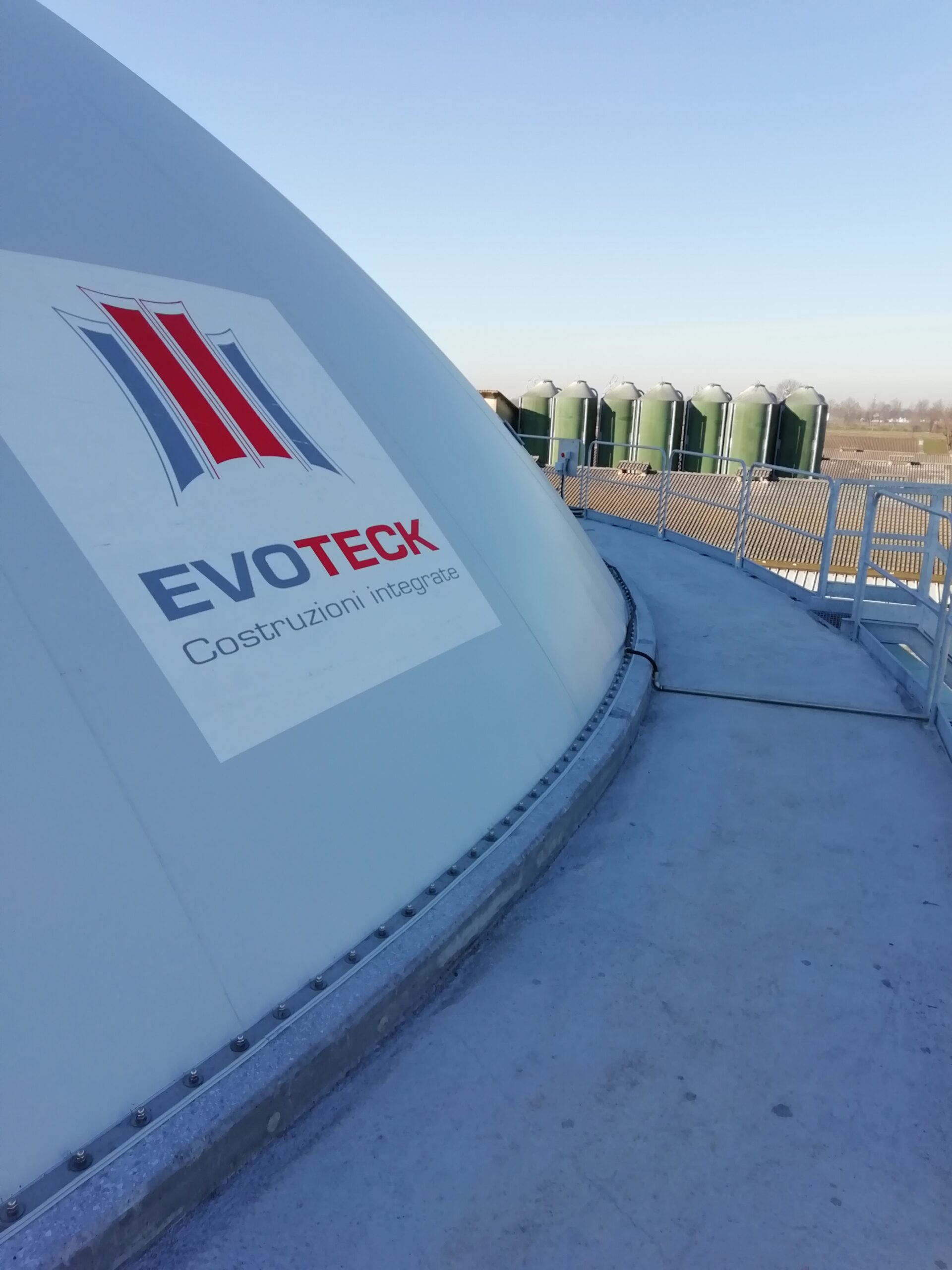

The COMPACT modular biogas plants are built with powers from 50 to 199 Kw and have been designed for small farms that decide to transform the products and waste of their business into electricity and heat and therefore into a profitable long-term investment. These plants are single-stage and therefore equipped with a single digester which can have a rigid cover (a prefabricated concrete slab) or a flexible cover such as a dome that also acts as a gasometer.

The works and systems that make up the system, while respecting a modularity, are made to measure for each project, adapting to existing structures and are designed to ensure the correct and continuous operation of the system with the available matrices.

For the agricultural company that today finds itself fighting in an increasingly global market, it is necessary to differentiate its business by trying to maximize the profits deriving from the products of its own company and having a biogas plant is certainly a winning choice!

BIOGAS PLANTS SUPERIOR

The SUPERIOR modular biogas plants are built with powers starting from 200 kW and have been designed for medium-large farms and livestock farms that decide to transform the products and waste of their business into electrical and thermal energy and therefore into a profitable investment. long-term. These implants, depending on the size and the matrices available, can be single-stage or two-stage.

Digesters are one of the leading products of our Company which, after years of research and development and dozens of realizations, we produce in our factory according to a completely innovative prefabrication and assembly system on site which aims to guarantee high resistance. to corrosive products produced during anaerobic digestion and a duration exceeding the total life of the plant as a whole.

The prefabrication system of the digester walls is by means of prestressing guarantees a complete absence of micro-cracks in the concrete (not achievable with classic tanks built on site), all reinforced by the use of SCC concrete with guaranteed minimum resistance Rck equal to 60 Mpa (class C 40/45).

For the cogeneration part, our Company makes use of guaranteed international producers who are able to guarantee assistance 24 hours a day, even in remote assistance.

The plant is managed completely automatically by a centralized PLC which acts as the brain of the plant. Through a custom-built software, the user can set and control each phase of the plant’s operation by keeping all the vital and non-vital factors for a biogas plant under control.

The systems are modular to reduce costs, but despite this they are made as a tailor-made suit for each customer to integrate it in the best possible way within your company.

For the agricultural company that today finds itself fighting in an increasingly global market, it is necessary to differentiate its business by trying to maximize the profits deriving from the products of its own company and having a biogas plant is certainly a winning choice!

BUNKER SILO

Resistant to chemical corrosion and with long durability.

Our company is able to produce prefabricated silos for the storage of the ensiled products having a maximum height of 5mt.

As required by the norm UNI EN206-1, the containing walls produced by us are in exposure class XA3 and therefore they are made with types of concrete having a minimum strength class C35 / 45 (Rck: 45 Mpa) through the use of pozzolanic concrete. A SCC (Self Compacting Concrete) concrete is also used, which reduces the porosity of the concrete to a minimum, increasing its durability and making the surface of the walls very smooth and, why not, aesthetically much more fine than the walls made on site.

These materials guarantee the walls against the chemical attacks of the ensilages and therefore a long durability over time.

The use of prefabricated components makes it possible to create silos in a very short time compared to those made on site.