BIOMETRICS

In the poultry sector, it all takes place in a short time and it is essential for those who manage to know in real time the progress of all production parameters to avoid an unforeseen event, that can turn into a concrete loss. Evoteck gives great importance to the automation of the process which is the core of a production system. Each parameter must be managed by a single control system since all are connected together and the changing of one can lead to bad consequences for all the others that then have to be automatically and abruptly adjusted to the trend and to the general requirements of the system.

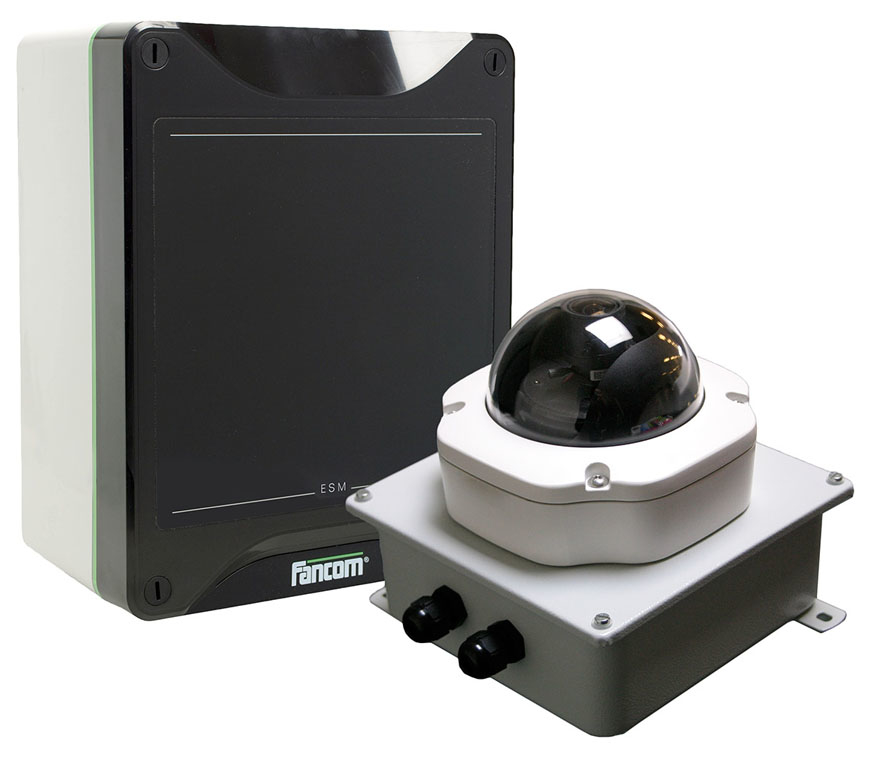

The central brain consists of several hardware and sensors and a central software that, thanks to complex algorithms, collects data, processes and manages the entire process, informing immediately the operator about any problem and providing at all times the data about consumption, cost and productivity.

Among the controlled processes are: the feeding system and the watering, the ventilation system, heating and cooling, the lighting system, the animal weighing, the driving systems and egg-counter system, the manure discharging system, the emergency system and alarm; each of them is a critical link in the complex chain of managing a modern agro-industrial complex that, to keep up with the times and to achieve the highest efficiency, must adopt these technologies.