SST FEEDING TROUGHS

They are produced in cast-in-place or self-supporting models, both made of AISI 304 STAINLESS STEEL; besides, the troughs are available in “double” or “single” models and in several sizes.

They are ideal for finishing, weaning or gestation environments.

In the “disposable” version, the troughs are equipped with an internal reinforcement rebar and are filled on site with concrete.

In the “self-supporting” version, they are built using a robust stainless steel tubular frame that can be fixed to the floor by means of anchor bolts or stainless steel anchors.

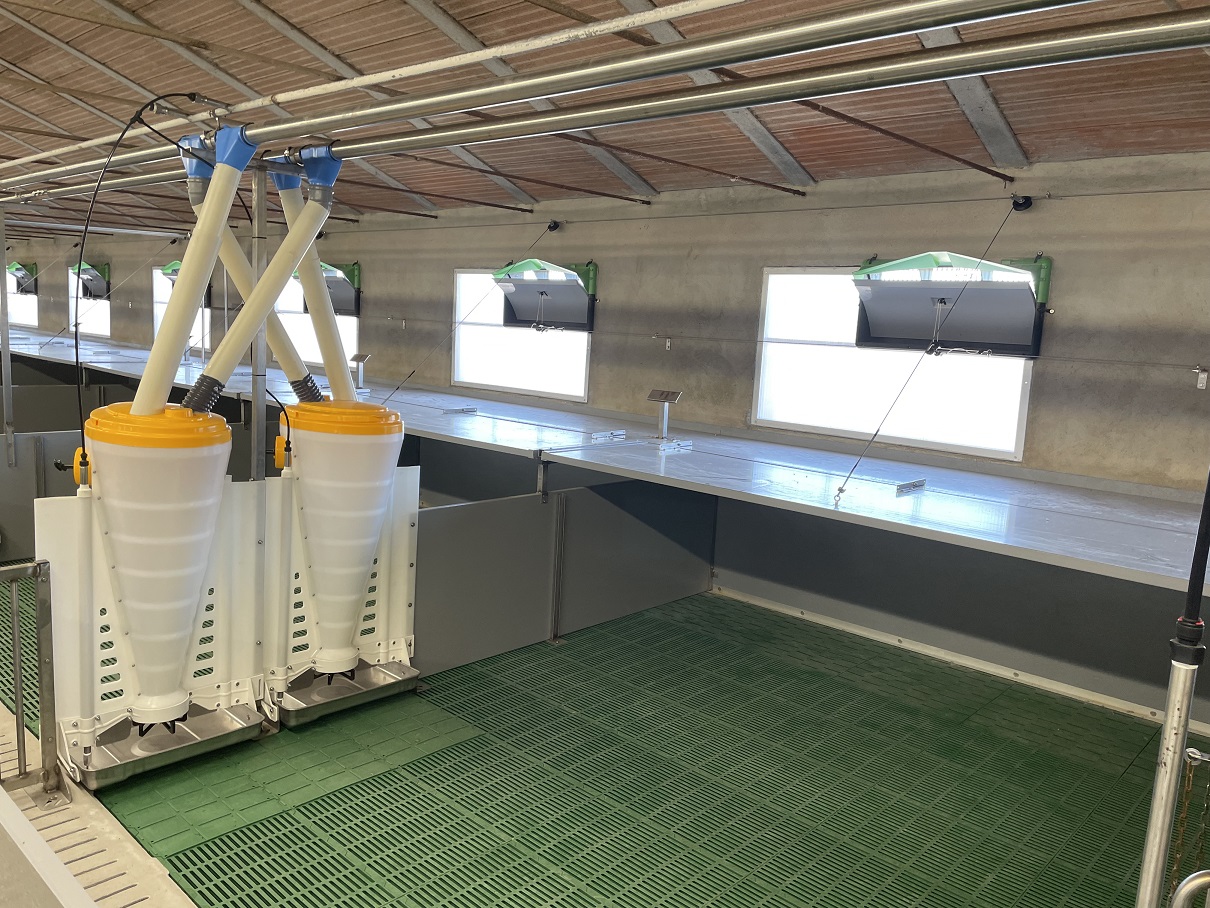

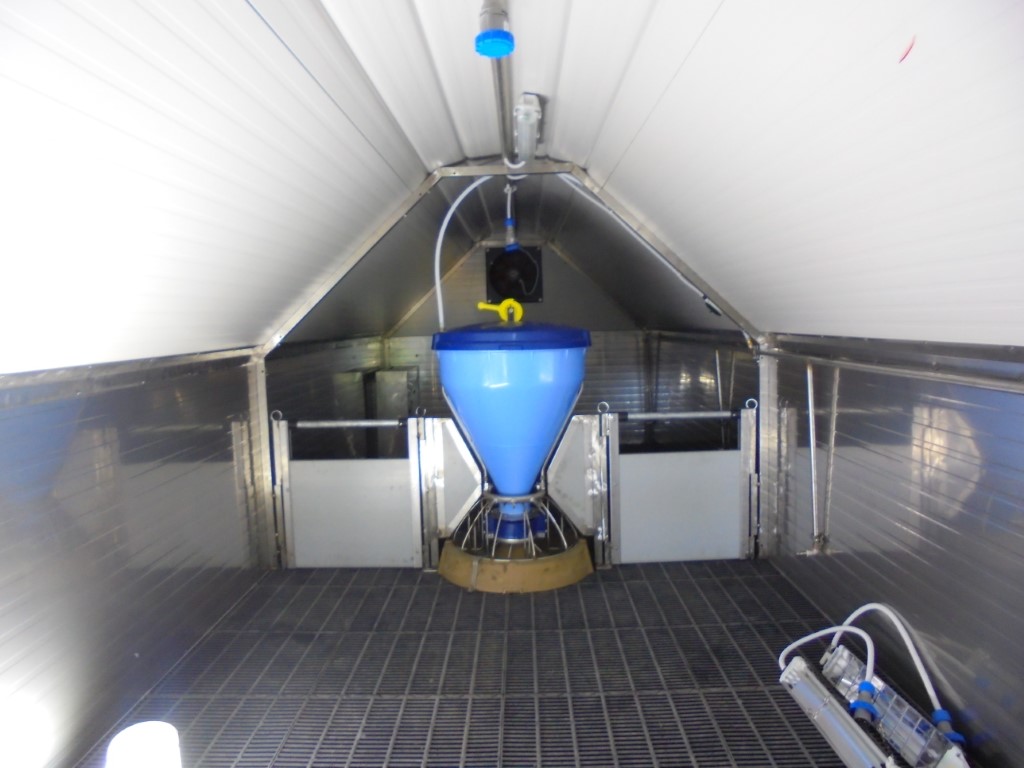

FLOORING SYSTEMS FOR FINISHERS

REINFORCED CONCRETE SLAT

We produce 10, 12, 14 and 18 cm-high reinforced concrete slats for finishers in compliance with the regulations. The maximum length is 360 cm.

On request, it is possible to make a reduction at the ends to meet level needs.

TERRACOTTA FLOORING

We produce solid floors by using terracotta-ribbed flooring blocks measuring 25 x 50 cm, 6 cm wide, conveniently laid out on a mortar bed. The presence of grooves allows the waste can be conveyed to the gutter.

HEAT-INSULATING FLOOR

The heat-insulating floor is characterized by cellular macro-structures that prevent the absorption of moisture increasing thermal comfort. It ensures that the animal is in good health and environmental condition. It is washable, crack-free, and resistant to all types of disinfection. It maintains the temperature of the stable and does not take heat away from the animals. A minimum thickness of 4 cm per square metre is recommended