SYSTEMS

Fill in the Form to Request Information

LIGHTING SYSTEM

We offer LED lighting systems for poultry farms, fruit of long experience and designed to have the maximum ratio between lux/m2 and energy consumption. The lamps are built with a strong anodized aluminum structure and a resin casting made during production ensures adequate heat dissipation of the electronic components, greatly increasing their useful life.

The lamps we install are oriented both to greater energy efficiency and to an increase in productivity of farms and are different from the others on the market for a long series of advantages:

– Speed in the wiring system;

– Width of the light beam;

– Accuracy in regulation;

– Homogeneity of light;

– Reliability of materials;

– IP69K water resistance.

Lamps with UV LEDs are available on request.

PAD-COOLING SYSTEM

The Pad-Cooling system is an efficient air cooling and humidification system used in departments where highly efficient and manageable cooling is required to cope with too hot periods that would lead to a very high level of animal mortality.

Thanks to a pumping station and through a pipe, water is circulated which, starting from a collection tank, is sent in an upper channel inside which, flowing, it is distributed and through special holes it falls downwards to the inside the evaporative panels, wetting them; The air entering the rooms, which are put in depression by means of fans, is obliged to pass through the evaporating panels; some of the water evaporates due to hot, dry air passing through the PAD. The rest of the water is exhausted into the pumping station via a lower water collection channel.

The heat required for evaporation is taken from the air itself. The air, after passing through the PAD, is then cooled and humidified simultaneously without any external energy source for the evaporation process: a completely natural cooling process.

The PAD-COOLING system is naturally automated and managed by the microclimate control unit which, according to the parameters to be obtained, regulates the functioning of the system.

This type of system is used in very hot and humid climatic zones, where the cooling with nozzles (cheaper) fails to obtain a sufficient yield.

FOGGING SYSTEM

We offer solutions of high-pressure fogging system for an effective humidifying, cooling and dust binding

of the house air.

It works according to the principle of the direct evaporative cooling.

Through high pressure nozzles water is injected into the house air with a pressure of 70 bar as fog.

The fog evaporates immediately and causes the cooling of the house air by extracting heat. This cooling effect saves energy because the ventilation rate can be throttled.

This system is used for the rise of the humidity to optimum value inside the house.

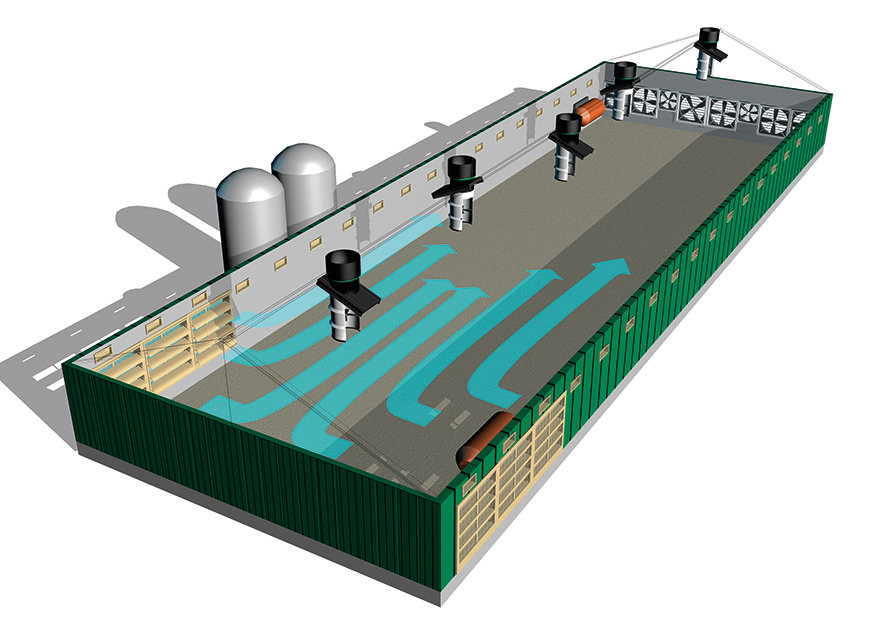

COMBI VENTILATION

The COMBI ventilation system is applied in moderate climates and provides an extraction through fans placed in the head of the shed or a combination of chimneys and fans in the head.

The air inlet is 100% through side windows or from the false ceiling.

These systems are normally combined with cooling systems with high pressure water.

The COMBI system is not ideal for outdoor conditions with high values of temperature and relative humidity.

MTT VENTILATION

The MTT system is the result of the union of three concepts of ventilation that corresponds to three phases of use of the system itself:

1. Minimum Ventilation;

2. Transitional ventilation;

3. Tunnel ventilation.

The minimum ventilation is foreseen to prevent periods in which it is required to have a low and controlled ventilation; in this phase the air enters through the winter windows on the sides and the output is regulated by head-mounted fans or with chimneys. The characteristics of this phase are:

– Elimination of harmful gases such as CO2, NH3, moisture and dust;

– Introduction of oxygen-rich air.

– Flow is well controllable and uniform even at low speeds.

– Particularly important with young animals still in development

– Reduces the risks of problems to the respiratory system of animals.

The Transitional ventilation operates when the ventilation level increases and is an intermediate step before switching to the Tunnel system. The aim of this phase is to move gradually from the Minimal system to the Tunnel system in order to avoid disturbances in the air flow. The characteristics of this phase are:

– No noise caused by inputs that open or close and no major changes in light intensity.

– Avoid stress to the animals and ensure a relaxing environment;

– The flow gradually changes from transverse to longitudinal;

– Animals do not migrate and remain distributed throughout the shed;

– During this phase the minimum ventilation works at maximum speed and the on/off fans are inserted one after the other while the windows continue to open.

– The system considers the age of the animals and avoids excessive air speed, as long as the animals do not have feathers yet.

Tunnel ventilation is essential to remove heat produced by animals. In this phase the winter side windows are completely closed and the summer windows, positioned on the opposite side with respect to the extraction fans, are automatically opened as required. The characteristics of this phase are:

– The fans positioned in the head create the tunnel effect with high air speed.

– Creates a cooling effect thanks to the air speed.

– It is possible to integrate the MTT system also with a PAD-COOLING to increase the cooling capacity. In this case the Pad Cooling is activated automatically by the control unit based on the request of animals.

TUNNEL VENTILATION

The TUNNEL ventilation system is applied in hot climates and provides a extraction through fans placed in the head of the shed and an air inlet is made at 100% through side summer windows positioned on the side opposite to the suction fans.

This ventilation system allows cooling thanks to the air speed, but is normally combined with a PAD-COOLING system.

The TUNNEL system is ideal for hot climates as it allows good control of temperature values; on the contrary it is not an ideal system for climates with low temperatures.

NATURAL GAS – DIESEL HEATING

We make poultry sheds heating systems using heaters equipped with gas burners (LP or natural gas) or on request with diesel oil.

These heaters are produced in various versions:

– External machines: they are positioned outside the shed, where necessary and they extract the air either from inside or outside and they re-introduce the heated air into the environment;

– Internal machines: they are positioned inside the room;

– Direct exchange: the combustion fumes are introduced into the environment of the shed; This solution is cheaper, but not recommended in case of prolonged and constant use of the same.

– Indirect exchange: the combustion fumes are expelled outside the shed after having heated, by means of an exchanger, the extract air, then re-injecting it into the environment of the shed.

HOT WATER HEATING

We propose hot water heating solutions for poultry farms that reduce CO2 emissions inside the premises and consequently reduce the need for ventilation and increase the well-being of animals and operators.

The system needs a thermal power plant that generates sufficient thermal power in the form of hot water and through specially balanced circulation lines, it is possible to power the unit heaters designed to ensure a homogeneous launch of hot air.

The heaters are heat exchangers that recirculate the hot air and guarantee energy savings both because reusing the hot air present in the ridge and because they do not produce CO2 and therefore it is possible to lower the minimum ventilation and consequently the heat output necessary to heat up incoming air.

The system can be divided into different zones and an air heater or a group of them can be managed individually according to the probes dedicated to the sector itself.