FARROWING

FARROWING PEN FOR LOOSE SOW – LIBERTY MODEL

There are several solutions for housing sows during farrowing, but the most current in terms of animal well-being is certainly the loose farrowing pen.

This type of farrowing pen makes use of large surfaces (from 5.5 to 7 m2 and more per pen) allowing the sow to spend most of the time free from the constraint of the cage, which considerably lowers the levels of stress and cortisol related to such condition; the sow is thus free to get up and lie down naturally or create a nest. However, the sow may be confined in the cage during the days strictly necessary for farrowing in order to minimise the mortality of the piglets during the early stages of life; she is then released into the pen, which is equipped with an area not accessible by the sow within which the piglets can rest peacefully.

Each type of loose farrowing pen can be completed with various types of feeders, flooring, water supply system and other complementary accessories.

MOD. LIBERTY MODEL is a farrowing pen from 5.5 to 7.0 m2 and above:

– side or rear sow access;

– can be opened/closed quickly and easily;

– trapezoidal or triangular nests for piglets;

– adjustable in length when closed;

– hot-dip galvanized steel sides and accessories;

– stainless steel feet;

– inexpensive.

FARROWING PEN FOR LOOSE SOW – FLEXI PEN MODEL

Farrowing pen: from 6.0 to 7.0 m2 and above:

– maximum optimization of the surfaces in the farrowing pen;

– side sow access;

– the sides can be lifted to “high position” during the free sow phase;

– useful width between the sides when closed: 65 cm;

– rectangular piglet nest up to 1.3 m2/pen located on the corridor;

– hot-dip galvanized steel sides and accessories;

– stainless steel feet.

FARROWING PEN FOR LOOSE SOW – EASY FRONT MODEL

Farrowing pen: from 6.0 to 7.0 m2 and above:

– front sow access through the opening front gate;

– feeder mounted on the front gate positioned flush with the corridor to allow easy inspection and cleaning without the operator having to enter the pen;

– rectangular or trapezoidal piglet nest;

– hot-dip galvanized steel sides and accessories;

– stainless steel feet.

ADJUSTABLE PLUS MODEL

The ADJUSTABLE PLUS model is the big sister of the compact adjustable model, because the characteristics are the same, but they allow to host genetics that require more space.

It is an adjustable elongated crate body in hot galvanized steel consisting of a rear gate and two sides made of round tube.

At the front the sides are fixed to a support arch that can be in galvanized steel or in stainless steel (which also acts as a water distribution system) and to it is also fixed the feeder for the sow.

The cage is set up with an anti-crushing device mounted on the side panels, designed to keep the sow lying slowly.

The ADJUSTABLE PLUS cage can be easily adjusted in length by means of telescopic inserts that allow the operator to easily change the length of the cage; the minimum length is 1900mm and the maximum is 2300mm and it is possible to have intermediate steps of 2000, 2100 and 2200mm.

The cage is also easily adjustable in width with 5 different settings.

The types of feeder applicable to this cage are multiple:

– Fixed feeder;

– Tilting feeder (to allow the sow to come out from the front);

– Rotating feeder (to allow a quick and convenient washing of the bowl).

All the versions of the feeder can be in polyethylene or stainless steel.

EVOLUTION MODEL

The EVOLUTION crate model is a crate made of hot-dip galvanized steel consisting of a rear gate and two sides made of round tubes that can be opened totally thanks to the hinge on the front arch.

The latter can be in galvanized steel or in stainless steel (which also acts as a water distribution system) and it is also fixed the bowl for the sow.

The sides are fixed to the appropriate fixing base, or under the sow floor in galvanized steel, which must be prepared with two inserts for hooking,

The cage is set up with an anti-crushing device mounted on the side flanks, designed to keep the sow lying slowly. This device can be adjusted to have different settings for the useful width of the cage.

The Evolution cage can be easily adjusted in length and is available in two versions:

1) EF1 version: The cage has two adjustments in length (1900 mm and 2100 mm approximately).

2) EF3 version: The cage has two adjustments in length (1750 mm and 1950 mm approximately).

Both versions have the feature to be adjusted, during the assembly phase, the space between the anti-crushing devices and have an optimal adjustment in respect the genetic needs of the animals.

The types of bowl feeders applicable to this cage are multiple:

– Fixed feeder;

– over tilting feeder (to allow the sow to come out from the front);

– Rotating feeder (to allow a quick and convenient washing of the bowl).

All versions can have the bowl feeder in polyethylene or stainless steel.

ELEVOTECK SYSTEM

By adopting the technology of ELEVOTECK our company guarantees the total care during the complete permanence in the farrowing room. Through the use of sophisticated mechanism with a sensor, the step of the sow lifts up from those of piglets, by the moment she stands up. On the contrary, when she lays, the level of the sow returns in the normal position at the same level of the piglets. That means, the sow lays down always when the piglets are on a safe level. The collected data on this system by the Universities give us clear ideas about the investment: The mortality of the crushed piglets, reduces up to the 80%, and together with that it reduces the labour costs to supervise it; The result of all is a an immediate and economic return for the farmer.

ELEVOTECK is perfectly integrated with the famous coated Evoteck slat (in the versions in expanded metal and double wire) that is produced by dimension in order to answer to the dimensional needs of the customer.

The union of both produces an avant-garde product for what concerns safety and comfort in the farrowing units.

Moreover, the pneumatic system is in serial connected and centralized, and it is possible to preview a manual control, to make the cleaning and maintenance.

During the automatic control each farrowing unit is independent , and works taking care of the sow behaviour 24 a day. All components have been chosen to guarantee long life and easy maintenance.

There are 3 versions of ELEVOTECK that differ in length: 2050, 2100 and 2200 mm.

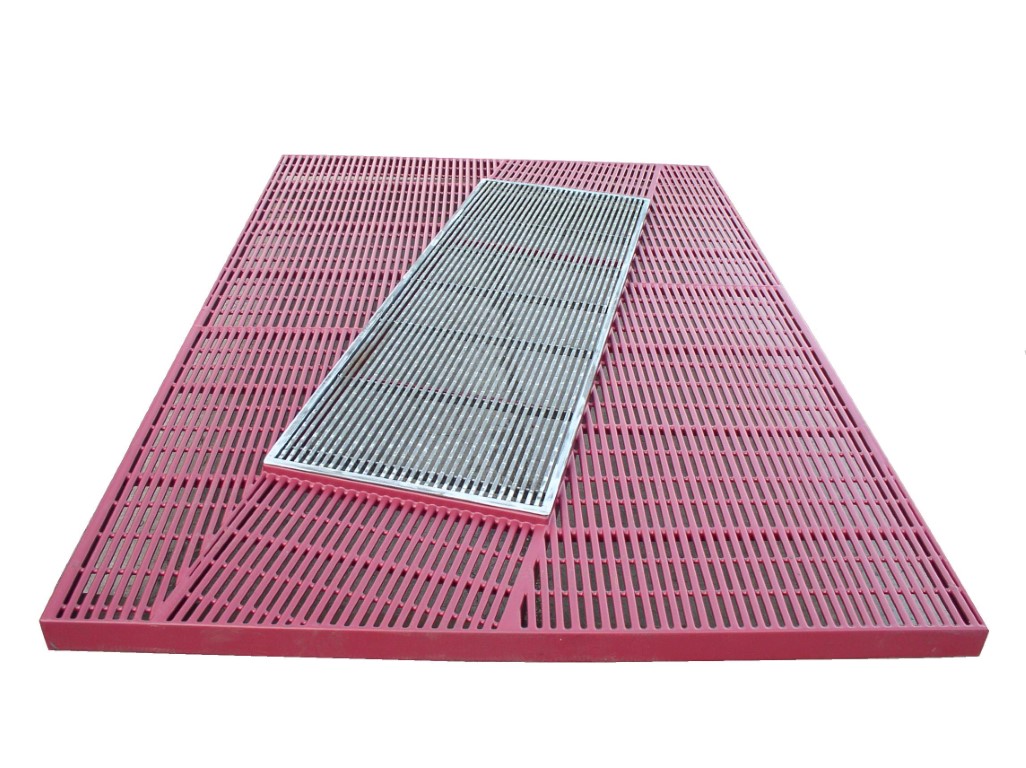

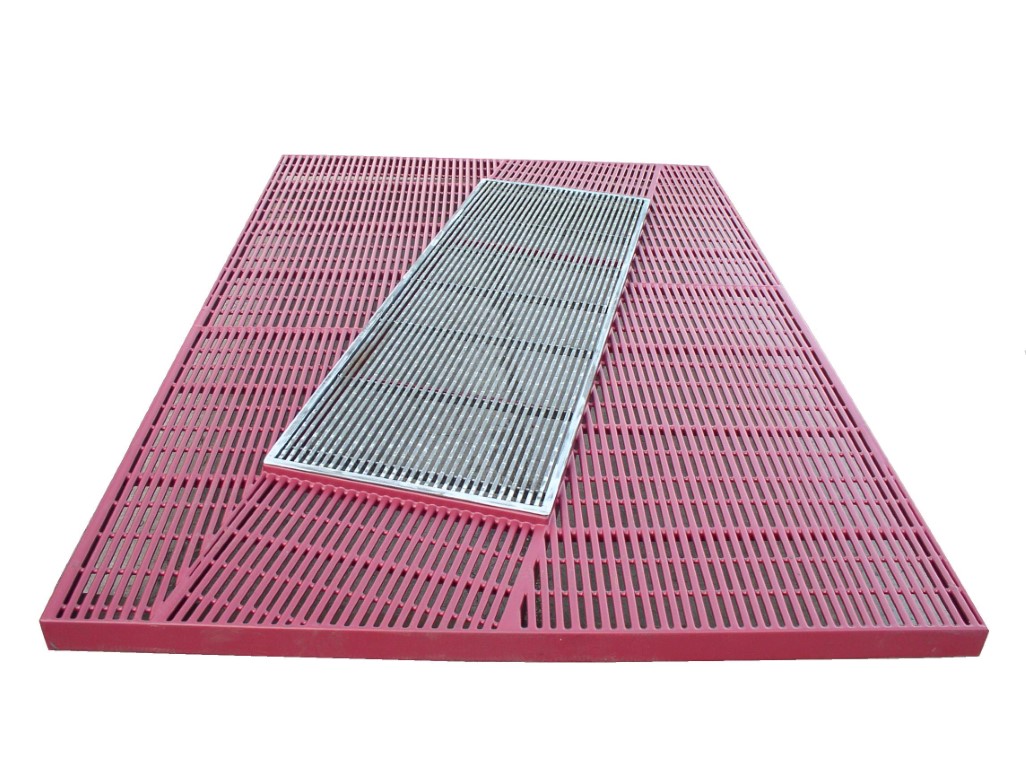

POLYPROPYLENE FARROWING SLATS

Depending on the request we can supply polypropylene flooring suitable both for piglets in weaning phase and for sows in the farrowing room. Both can have a supporting structure made of galvanized or stainless steel plates or using fiberglass profiles.

SOFT COATED FARROWING SLATS

GALVANIZED TRI-BAR SLATS

The great cleanliness and quality of materials characterize the gratings made with a supporting frame made of profiled steel wire and triangular, all carefully hot GALVANIZED.

They are suitable to be used for different types of animals.

This slat is characterized by its robustness and precision construction through to production with automated machines, in spite of this it is possible to produce tailor-made.

The upper triangle is textured, providing a perfect surface for the sow Anti-slide or other animals.

It can be used both as under-sow in the farrowing room as flooring in the corridors in the various departments of farm.

PVC FENCES

The fences between cages are made of strong 35 mm thick PVC panels supported by stainless steel posts; all fastened by stainless steel accessories and bolts.

According to the type the type of farrowing cage (fixed or liberty) we propose different height of partitions:

– Height 50 cm for traditional farrowing pens;

– Height 85 or 100 cm for free-sow pens.